Payout Reel

Straightener

Servo Feeder

Cupping Machine

Recoiler

Washing Machine

Annealing Oven

Pickling Machine

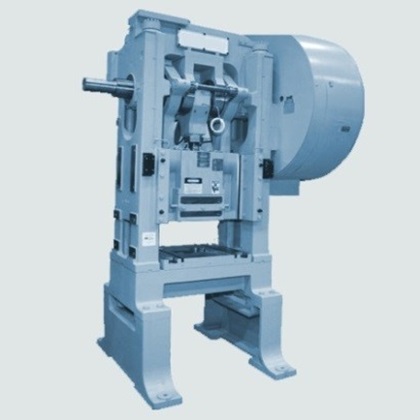

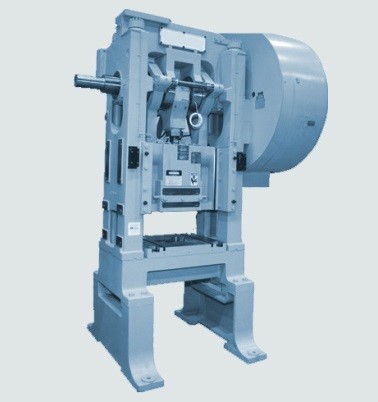

CARTRIDGE CASE CUPPING MACHINE

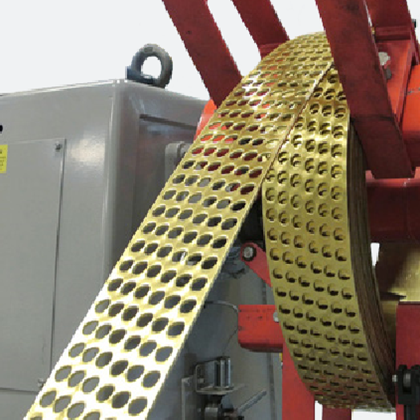

Cupping Presses from SAE can be used to produce cups for bullet jackets, cartridge cases and various other cases. Cup sizes can be up to 20 mm in brass. For this model, it covers all small pistol, small and large rifle calibers up to and including .50 cal.

| TECHNICAL DATA | |

|---|---|

| TITLE | MEASUREMENTS |

| Capacity (maximum) [tn.] | 70.00 outer, 90.00 inner |

| Stroke-cutting slide [in.] | 2.00 |

| Stroke-drawing slide [in.] | 5.00 |

| Shut height-bed to cutting slide [in.] | 13.00 |

| Shut height-bed to drawing slide [in.] | 16.00 |

| Adjustment of cutting slide [in.] | 1.00 |

| Adjustment of drawing slide [in.] | 2.00 |

| Speed [spm] | 140.00 |

| Clutch w/ brake | #372 CKU |

| Motor horsepower [hp] | 15.00 |

| Area of bolster [in.] | F-B 24.00, L-R 31.00 |

| Floor space [in.] | F-B 71.00, L-R 94.00 |

| Height [in.] | 142.00 |

| Weight [lbs.] | 26,000.00 |

| Control Cabinet [in.] | Nema 12, 36” x 60” x18” floor standing |

| Electrical Supply | 220/240/380/440 three phase |

| Control Voltage [VDC] | 24.00 |

| Compressed air requirements [psi] | 70 @5.5cfm (3/4 NPT pipe inlet) |

| Lube oil supply [gal.] | 1.50 |

Cupping Machine

CARTRIDGE CASE FEED EQUIPMENT

Payout Reel

Straightener

Servo Feeder

Recoiler

FEED EQUIPMENT PRODUCT INFORMATION

SAE can supply feed equipment for all of your munition press applications. SAE uses the latest state-of-the-art feeding equipment and can work with you to develop the proper solution for your production needs.

Payout Reel

| 2,500 lb. Capacity, Single Arbor, Non-Motorized Payout Reel | ||||

| SPECIFICATIONS | ||||

| Maximum Material Width | 12 in. | Maximum Arbor Capacity | 2,500 lbs. | |

| I.D. Expansion Range | 16 to 20 in. | Maximum Coil OD Capacity | 48 in. | |

| STANDARD FEATURES | ||||

| Adjustable Tension Pneumatic Drag Brake | Simple Mechanical Expansion | |||

| Heavy Duty Bearings | 3 Self-Centered Coil Support Shoes | |||

| Welded Steel Construction | Floor Lagging Holes | |||

| 3 Quick Release Coil Keeper Arms | ||||

Straightener

| Powered Straightener | ||||

| SPECIFICATIONS | ||||

| Maximum Material Width | 6 in. | Number of Straightening Rolls | Seven | |

| Maximum Material Thickness | .200 in. | Number of Pinch Rolls | Four | |

| Minimum Material Thickness | .025 in. | Payout Rate | 0 to 75 FPM | |

| Roll Diameters | 3.00 in. | Motorization | 3 Hp, 220V, 1Ph | |

| STANDARD FEATURES | ||||

| Roll Setting Scales | Loop Arm Speed Control | |||

| Variable Speed Drive | 110 V at Controls | |||

| Machined Side Plates | Entry and/or Exit Catenary | |||

| Fabricated Steel Mounting Cabinet | Reversing and Jog Switch | |||

| Air Lift Pinch Rolls | Hardened and Ground Rolls | |||

| Relube Type Bearings | Adjustable Entry and Exit Guides | |||

Servo Feeder

| Electronic AC Servo Driven Roll Feeder | ||||

| SPECIFICATIONS | ||||

| Maximum Material Width | 6 in. | Maximum Feed Length | 0 to 9999.99 in. | |

| Stock Thickness Capacity @ Full Material Width (Based on Mild Steel) | .250 in. | Roll Position Accuracy | ± .002 in. | |

| Feed Roll Diameters | 3.250 in. | User Supplied Incoming Voltage | 440V, 3Ph, 60Hz | |

| FEATURES | ||||

| Pneumatic Pilot Release | ||||

| Precision machined dowel pinned and bolted construction. | ||||

| Brushless AC Servo Drive closed loop feedback system with control diagnostics. | ||||

| Remote pendant control - Jog forward and reverse - with coiled cord. | ||||

| Driven upper and lower precision ground feed rolls. | ||||

| Matte finish on feed rolls (Optional Crodon finish.) | ||||

| Master control box with data entry keypad and LCD display on pedestal support. | ||||

| Independently adjustable input side guide rolls. | ||||

| Unique planetary gear cluster maintains full helical gear drive contact of upper roll regardless of material thickness. | ||||

| Heavy-duty timing belt drive between drive and lower feed roll. | ||||

| Adjustable press mounting bracket, slotted for ± 2 in. of adjustment. | ||||

| Three roll cascade catenary. | ||||

| Centralized lubrication fitting manifold block. | ||||

| Feed signal and pilot release signal. | ||||

BRUSHLESS AC SERVO DRIVE:

State-of-the-art motor control package.

Feed speeds and performance designed to match your specific press applications.

Conservatively rated, capable of very high peak torques

Diagnostic display of operating status.

Recoiler

| 1,500 lb. Capacity, Single Arbor, Motorized Take-up Reel (Recoiler) | ||||

| SPECIFICATIONS | ||||

| Maximum Material Width | 12 in. | Maximum Arbor Capacity | 1,500 lbs. | |

| I.D. Expansion Range | 12 to 20 in. | Maximum Coil OD Capacity | 48 in. | |

| Motorization | .5Hp DC, 120V, 1Ph | Arbor Speed Range | 0 to 28 RPM | |

| STANDARD FEATURES | ||||

| Variable Speed DC Regenerative Drive | Reversing Switch | |||

| Jog Control | Loop Arm Speed Control | |||

| Heavy-Duty Bearings | 3 Self-Centered Coil Support Shoes | |||

| Welded Steel Construction | Floor Lagging Holes | |||

| 3 Quick Release Coil Keeper Arms | ||||

WASHING MACHINE

WASH EQUIPMENT PRODUCT INFORMATION

The wash and pickling systems are flexible and can be used as part of an

in-line parts washer and/or

pickling system. Smooth tumbling action maneuvers parts to expose all edges and surfaces as they are sprayed

and immersed in the cleaning and rinsing solutions. Dryer stations can be added as required. All stainless

steel construction is used for the tank, drum, and drum housing to ensure many years of reliable

service.

SAE can supply cleaning and pickling equipment to meet all of your munition applications. SAE uses the

latest state-of-the-art in cleaning and pickling equipment and can work with you to develop the proper

solution for your production needs.

TECHNICAL INFORMATION

The Rotary Drum Washing System continuously feeds parts through a rotating drum. As the parts are advanced

through the drum, they pass into cleaning, rinsing, rust inhibiting and drying sections. This design enables

a large quantity of parts to be economically processed.

The parts are gently tumbled in the aqueous solution, providing a very effective method of exposing all

edges, surfaces, and blind holes to the immersion, high pressure spray, and high solution delivery cleaning

action.

The engineered drum, spray system and recirculating dryer eliminate waste and non-value-added time from your

manufacturing process while improving product quality and reducing energy and floor space

requirements.

Proper weld construction of the drum and helix, as well as proper helix spacing, vertically positioned

headers, and a dryer design that does not use a snorkel tube will eliminate potential for part mixing due to

lodging, bridging, and part hang up.

Washing Machine

ANNEALING OVEN

Annealing Oven

Annealing Oven

ANNEALING EQUIPMENT PRODUCT INFORMATION

SAE Industries can supply annealing equipment to meet all of your munition applications. SAE offers multiple-sized ovens for all calibers for annealing brass case cups and cases as well as copper bullet jackets. Electric ovens are available with multiple controlled heating zones. SAE utilizes the latest state-of-the-art annealing equipment and can work with you to develop the proper solution for your production needs.

TECHNICAL INFORMATION

| ELECTRIC | MEASUREMENTS |

|---|---|

| Part : | Cups and Cases |

| Max. Weight : | 13g (0.03 lbs.) |

| Cross Section : | 5mm (0.2”) |

| Production Rate : | 900 parts/min |

| Thermal Capacity : | 800 kg/hr. @ 425°C (1,765 lbs./hr. @ 800°F) |

| Belt Speed : | Adjustable between 100 to 600 mm/min for a cycle of 10 to 60 minutes. |

PICKLING MACHINE

Pickling Machine

PICKLING MACHINE PRODUCT INFORMATION

Similar in function and appearance to the Washing Machine, the Pickling Machine is used as an in-line parts pickling system. Smooth tumbling action maneuvers parts to expose all edges and surfaces as they are sprayed and immersed in the pickling solution. Dryer stations can be added as required. All stainless steel construction is used for the tank, drum, and drum housing to ensure many years of reliable service. Compared with the Washing Machine, the Pickling Machine is upgraded to SAE 316 Stainless Steel.

TECHNICAL INFORMATION

The Rotary Drum Pickling System continuously feeds parts through a rotating drum. As the parts are advanced

through the drum, they pass into pickling, rinsing and drying sections. This design enables a large quantity

of parts to be economically processed.

The parts are gently tumbled in the acidic pickling solution, providing a very effective method of exposing

all edges, surfaces, and blind holes to the immersion, high pressure spray, and high solution delivery

pickling action.

The engineered drum, spray system and recirculating dryer eliminate waste and non-value-added time from your

manufacturing process while improving product quality and reducing energy and floor space requirements.

Proper weld construction of the drum and helix, as well as proper helix spacing, vertically positioned

headers, and a dryer design that does not use a snorkel tube will eliminate potential for part mixing due to

lodging, bridging, and part hang up.